An important and often confusing topic is how changes affect the bill of materials where a changed component or subassembly are used. Does changing a component also necessitate changing the BOM? And if yes, which levels of the BOM have to be changed? The clear answer is, it depends on the situation or case. Let’s break it down…

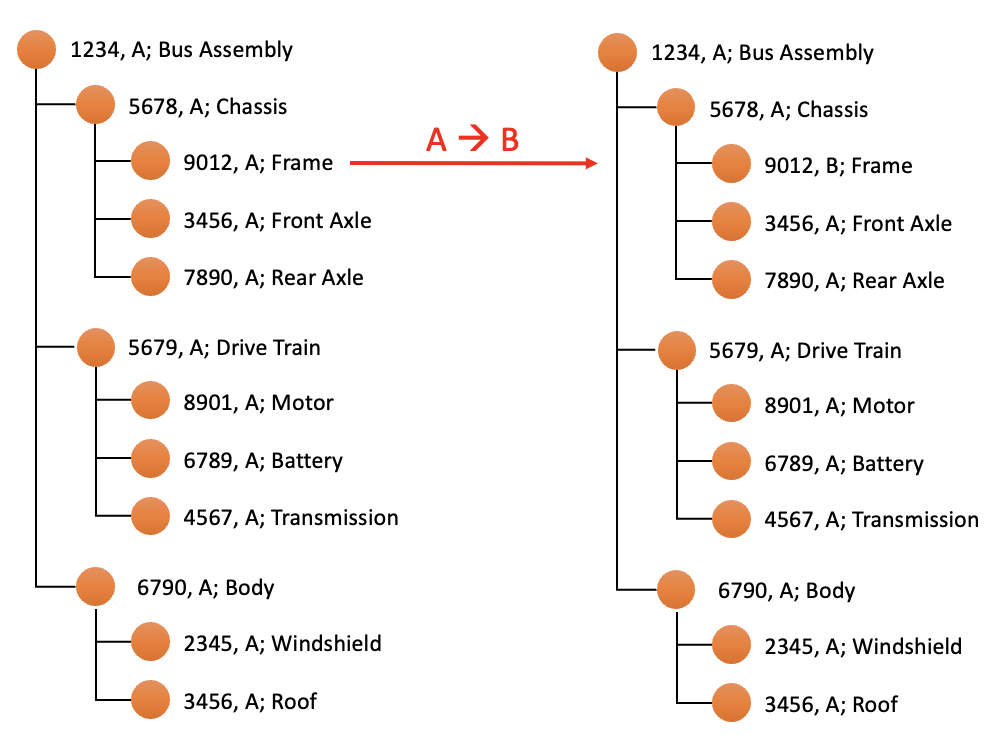

- The component can be revised, meaning the part number stays the same and only the revision changes. Following configuration management best-practice, this means form-, fit and function of the component are maintained and the new revision can fully replace the old revision, no matter where it is used (see also PLM Insight on Form, Fit & Function). As a matter of fact, from a logistical or operational point of view, there is no difference between the new revision and the old revision. In inventory for example, bins or locations are only distinguished by part number, not by revision. So someone picking a part from a bin in the stock room would not know whether they get an old or new revision of that part. Hence on the BOM it cannot matter whether a new or old revision is used, and so it is not necessary to revise the BOM on any level.

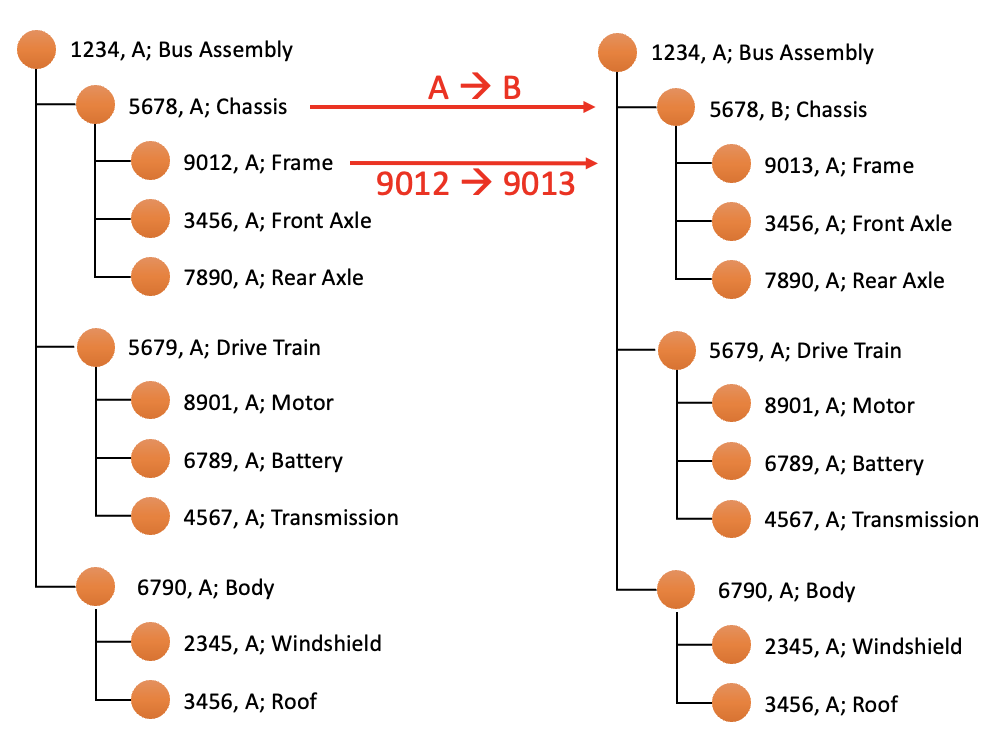

- The component cannot be revised, meaning form, fit and function are not maintained. In this case the existing part has to be replaced with a new part with a different part number. And this is where it gets a little complicated in terms of how the BOM is affected because there are two different scenarios:

- If form, fit and function of the next higher level of the BOM, or the assembly in which the component is used, is maintained, that assembly level can be revised, i.e. changed to the next revision level. Any higher level of the BOM does not have to be revised because again, the lower BOM level assembly is fully replaceable.

- If on the other hand form, fit and function of the next higher level of the BOM is not maintained, then the number of that assembly has to be changed as well, i.e. it becomes a new assembly with a new part number. This in turns requires determining how the next higher level of the assembly is affected. If that level maintains form fit and function, it can be revised. If not, it also has to be replaced with a new assembly with a new part number. And so on…

- If form, fit and function of the next higher level of the BOM, or the assembly in which the component is used, is maintained, that assembly level can be revised, i.e. changed to the next revision level. Any higher level of the BOM does not have to be revised because again, the lower BOM level assembly is fully replaceable.

All this of course is true if the components and assemblies have been released. If not, they can be modified without changing revisions or part numbers. In that case it may still be beneficial to maintain versions so that the design history is maintained and any modifications can be reverted to the previous state.

The conclusion is that doing a proper and detailed change impact analysis during the change request stage is critically important to determine which components and assembly levels of a BOM have to be revised or be replaced if any component on that BOM has to be changed.

Andreas Lindenthal, the author, is the founder and managing partner of PLMadvisors. He is a passionate thought leader and recognized industry expert with over 25 years international, hands-on experience in innovation, new product development (NPD), and product lifecycle management (PLM). He has served over 100 leading global companies across various industries to sustainably improve their business results by helping them to drive innovation, increase productivity, shorten time-to-market, reduce costs, ensure compliance and improve product quality through the resourceful utilization and integration of innovation, NPD and PLM practices, processes and technologies.