I often hear non-engineers asking this question: We already have ERP, why do we need PLM? And even engineers sometimes ask why it is not enough to manage engineering and CAD data in a PDM system.

The answer is, most manufacturing companies need both ERP and PLM. The main reason is that each of these systems has its own purpose, and each system integrates and enables a different process chain in the enterprise.

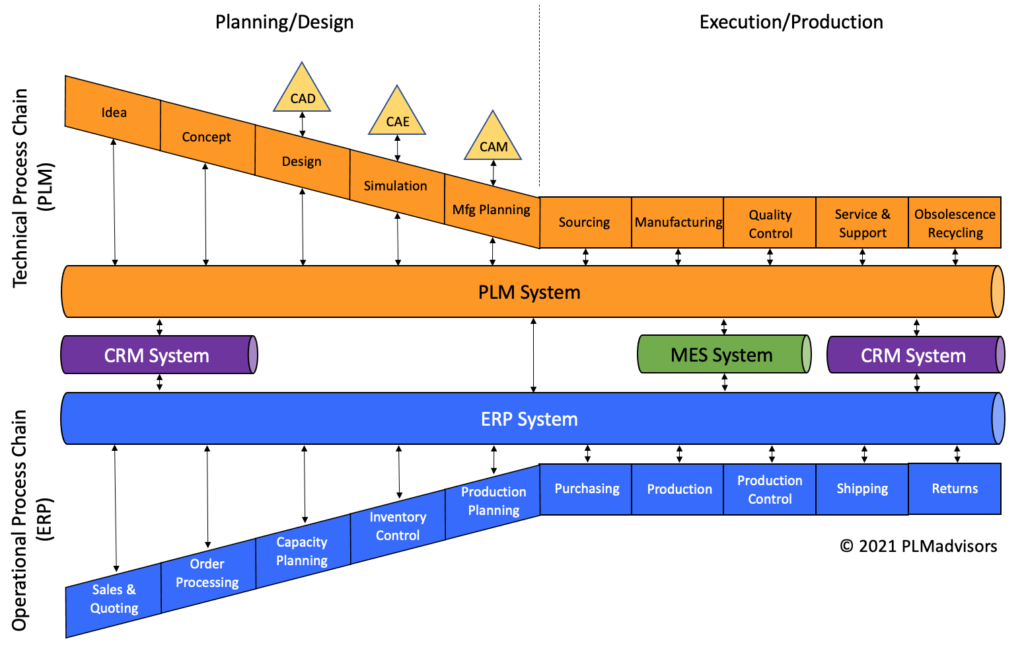

The ERP system integrates and enables the operational process chain. This includes functions like sales & quoting, order processing, capacity planning, inventory control, production planning, purchasing, production, production control, shipping and returns.

PLM on the other hand integrates and enables the technical process chain, which includes functions like ideation, concept creation, design, simulation, manufacturing planning, sourcing, manufacturing, quality control, service & support and obsolescence & recycling.

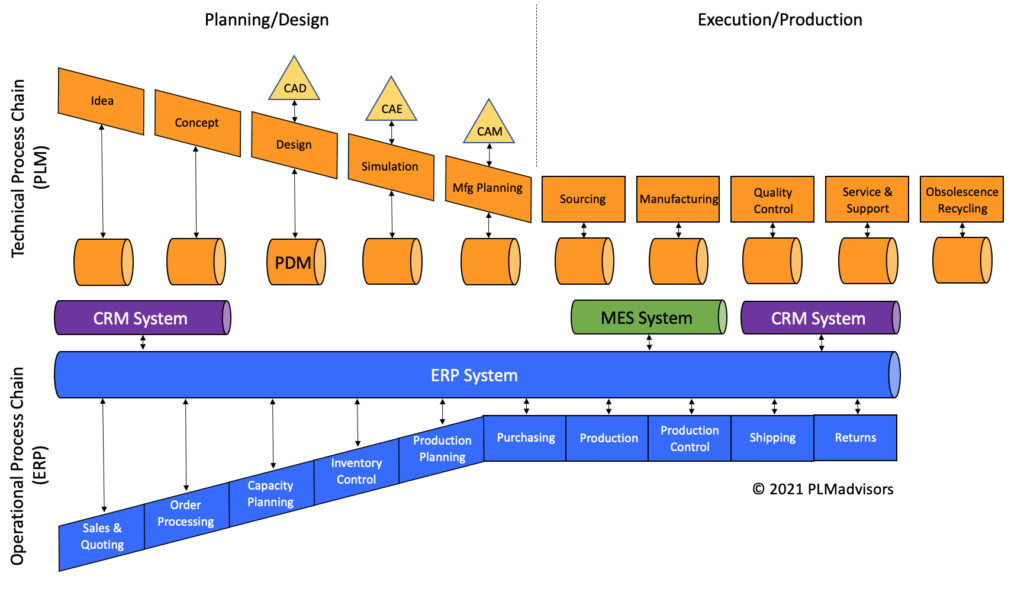

Without PLM every function in the technical process chain generally has its own data repository, which makes collaboration more difficult and increases the time required to pass information from one function to the other. In many instances it requires data to be entered multiple times in different systems, which is not only time consuming but also error prone. For example the CAD product structure, which could be in PDM, may have to be manually entered into an Excel spreadsheet to create the full EBOM, and part information may again have to be entered into yet another system to create manufacturing work instructions, etc.

The other maybe not so obvious challenge is that without a PLM system there are many systems in the technical process chain that potentially have to feed information into the ERP system, consequently requiring either multiple manual data entry efforts or the necessity to establish several system integrations to ERP.

Only by using both an ERP and PLM system together can a company integrate both the operational and technical process chains, increase the overall efficiency and reduce time to market and/or project delivery times, and lower the complexity and costs for IT as only one integration is required between PLM and ERP to transfer all the data between the systems.