What is a part number?

A part number is a unique identifier for a product, part or component within an organization that is the design authority for that part or component. According to MIL-STD-3046 – Configuration Management and ANSI/EIA-649B, “the product identifier, in conjunction with enterprise identifier, shall uniquely identify an item from all dissimilar items. The product identifier shall be changed whenever a non-interchangeable condition is created”.

What should the part number consist of?

ASME Y14.100-2004 specifies that the product identifier or part number shall consist of letters, numbers, or combinations of letters and numbers, which may or may not be separated by dashes or slashes that are assigned to uniquely identify a specific item. The part number shall be or shall include the design activity drawing number and may include a suffix identifier, when applicable.

Although the ASME standard allows for letters and numbers in part numbers, the recommended best practice is to use numbers only. The primary reason is legibility. It can be very difficult in some fonts to distinguish certain numbers and letters, especially 1 (one) and I, 2 (two) and Z, 5 (five) and S, 6 (six) and G, and 0 (zero) and O or Q. It can also be difficult to separate the product identifier from the revision if both contain letters. In an identifier that reads ABC-123-A, is the last A part of the identifier or is it the revision? It also is much more difficult to quickly memorize a sequence consisting of letters and numbers than of numbers only. And lastly, there is the possibility that the product identifier is mistaken for the part name if the former contains letters.

Best practice is to use numbers only for part numbers to avoid confusion with other elements of the part description, such as revision and name.

What is the best format for a part number?

Most companies will create millions of parts during their existence, so the part number has to account for that considering that each part number has to be unique. So it is common that part numbers contain at least 6 – 8 digits. That will allow the assignment of somewhere between one million and hundred million unique part numbers, assuming only numbers are used following the recommendation above. However, reading a continuous six- to ten-digit number is not easy, much less remembering it.

Best practice is to split up the part number in smaller, easier to read and remember chunks of three to four digits each, using dashes as separators between the chunks. Just like phone numbers. 102-938-475 is much easier to read and remember than 102938475.

Should a part number include information about the part?

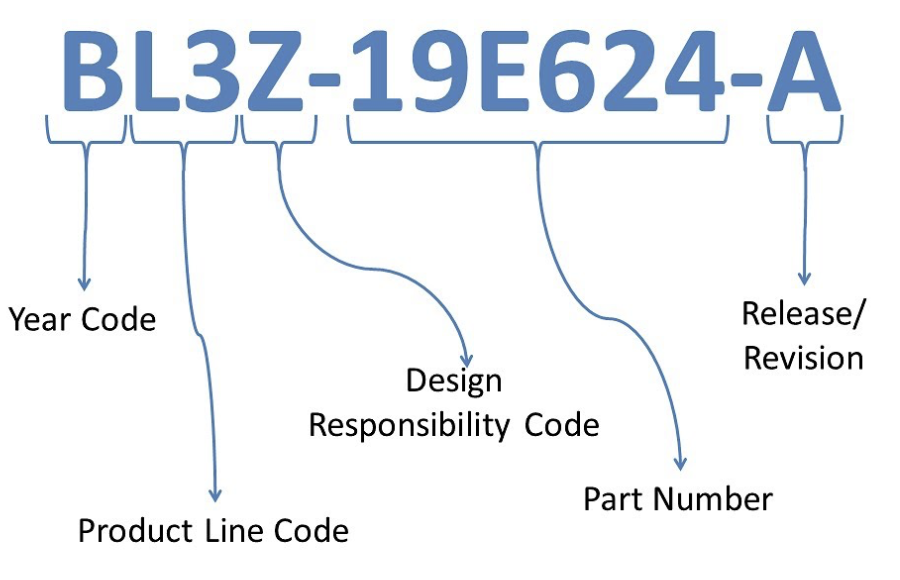

It is still common today for companies to use “intelligent” or significant part numbers, meaning information about the source, part type, the customer, and other things are coded into the part number. For example in a part number 1-18-2345-411, 1 would mean it is an in-house manufactured part, 18 would be for a spacer, 2345 would be a sequentially assigned number for spacers, and 411 would identify the customer or project.

Historically, i.e. in paper based environments, that could be beneficial in many cases, as it helped document control to archive and retrieve physical drawings and documents for the related parts more easily in the often sprawling file cabinets.

However, with today’s technologies these type of part numbering schemes are not beneficial anymore. To the contrary. PLM systems provide powerful functionality to organize and search parts and documents through various attributes, classifications, and even full text search.

Also, most PLM systems support assigning non-significant or sequential part numbers out-of-the-box, while the creation of significant part numbers usually requires customization, which can be very expensive not only to implement initially, but even more so to maintain in subsequent system upgrades.

And there are other disadvantages of significant part numbers.

- Significant numbering schemas are generally limited. If, as in the example above, the company uses two digits of the part number to define the part type (10 for bolts, 11 for nuts, 18 for spacers, 23 for sealings, 32 for transistors, etc), at some point it has used up all possible 99 types. What then? Force the new part type somehow in the old schema? Change the numbering schema to include 3 digits for the part type? Using non-significant part numbers together with a separate classification system is much more flexible, as an unlimited number of new classes or types can be added.

- With a significant number, a part can only have one type or classification. It is not possible to assign a part two different types or classes. But what if the same part could be used both as a spacer (18) and a sealing (23)? What number do we use in that case? Using non-significant part numbers with a separate classification system is more versatile as the same part can be assigned to several classes or types, i.e. a part can be classified and found as both a spacer and a sealing.

Best practice today is to use non-significant part numbers and utilize the available functionality of PLM systems to properly organize, classify and search parts and documents.

Should the part number include the revision?

A part number is a unique identifier for a part. That unique identifier indicates that, following the principle of form, fit and function, the part is 100% interchangeable with all other instances of that part wherever it is used, independent of the revision of the part.

From a configuration management point of view it doesn’t matter which revision is used on a BOM, so if the revision a part changes, we do not have to change the BOM (see PLM Insight “Change Management and BOMs (Form, Fit and Function, Part III)”). If the revision is included in the part number, we have to change every BOM on which the part is used every time the part is revised, which can create a lot of unnecessary effort.

From an operational point of view the part number also represents an inventory location where the part is stocked. If the revision is included in the part number we have to have a separate inventory location for each revision.

Best practice is to not include the revision in the part number.

Should the part number have a suffix?

It is common practice in many companies to use suffixes in part numbers to indicate similar parts or part families. For example, part number 123-456-001 may be a bolt M10 x 20, and part number 123-456-002 may be a bolt M10 x 25. Essentially the bolts are exactly the same, except for the length. The common portion of the part number (123-456) indicates that they belong to the same part family, the suffix indicates they are a little different. Historically the main reason and benefit companies use part families is to only have one drawing for all the parts of a family. That drawing would include a table for the parameters that are different between the individual parts. In the above case, the table would include two bolts, one of length 20 mm (123-456-001), the other of length 25 mm (123-456-002). The drawing number in this case would typically be the common portion of the part number, i.e. 123-456, but that’s not required. It could essentially be anything else too.

The challenge with this approach is when we have to revise one part of the part family. Say for example the bolt with 25 mm length has to have a red mark on it indicating that it is longer. It doesn’t change form, fit or function, and the new revision can fully replace all previous revisions, so a revision is possible. But how do we revise only one part of the part family? Of course the drawing will have to be revised to specify the red mark on the longer bolt. But if we revise only the drawing and the longer bolt, the shorter bolt now has a different revision than the drawing. That’s not ideal. The alternative is to also revise the shorter bolt, just to keep the drawing in sync with all part family members specified on that drawing, but that potentially creates a lot of unnecessary effort and confusion as now all suppliers may have to be notified of a revision that really doesn’t change anything, at least in the case of the shorter bolt.

With the functionality available in PLM systems today, there is no need to manage and maintain part families and specify multiple parts on one drawing. It is very easy to copy the shorter bolt for example with the associated drawing, modify the bolt to the new length of 25 mm, update the drawing and save the new bolt and related drawing with an entirely different part and document number. Attributes and classification allow us to indicate that they are similar and can be found together, irrespective of the part number.

Best practice today is to not use part number suffixes anymore and instead use available PLM system functionality such as attributes and classification to group parts together and find similar parts.

Andreas Lindenthal, the author, is the founder and managing partner of PLMadvisors. He is a passionate thought leader and recognized industry expert with over 25 years international, hands-on experience in innovation, new product development (NPD), and product lifecycle management (PLM). He has served over 100 leading global companies across various industries to sustainably improve their business results by helping them to drive innovation, increase productivity, shorten time-to-market, reduce costs, ensure compliance and improve product quality through the resourceful utilization and integration of innovation, NPD and PLM practices, processes and technologies.